If you’re at the range every weekend, at the very least, once a month, then you know how quickly your ammunition box runs dry.

Reloading is a money-saving hobby that helps you plan for just about anything. Ammunition shortages are a current and future threat. We know that because they’ve happened before, and with more people shooting, it’s getting more and more expensive to replenish what you shoot.

Instead, you can solve your own problem by reloading your own bullets.

It not only puts the fight in your hands, but it also allows you to customize your loads for specific needs and really make the bullets your own. Just be sure to stock up when you can get all of the components and get storage bins that will protect them from the elements. The best ammo storage containers will work equally well on completed bullets as with components for reloading.

If you enjoy shooting as much as we do, then reloading your own ammo is going to be well worth the time spent. Check out also these safety tips on reloading ammo at home.

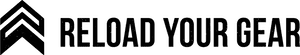

Reloading Aptitude Test . . . Really Just Fun 🙂

Scroll to the bottom of the article to check your answer!

Tools for Reloading Ammo

Reloading Manual

It contains all the basic information about the reloading process and is a reference for cases, powders, and bullets for the caliber bullets you wan to create.

Reloading Press

A reloading press is the primary tool for reloading your own ammo. You can pick anything from a single stage that will take lots of time to relatively automated units for true production environments and everything in between.

There are three main types of presses, and it’s important to understand the strengths and weaknesses before buying one. Our best reloading press article does a great job of walking you through that decision.

Types Of Reloading Presses

Progressive Reloading Press

Progressive reloaders are basically the number one type of press you can buy. They come with a casing hopper, completion bin, simple operating lever, and a power measurement system and are the best balance of precision, speed, and value for most shooters. Check out our picks of the best progressive reloading presses if you think that sounds like you.

They take the manual work out of reloading. This allows you to reload faster and save time, though it is at a higher upfront cost.

Progressive presses may come with a variation of attachments. For instance, some may not include a casing hopper, but you have the option to add one later on. Progressive presses are the hardest to maintain due to the extra parts, but a worthy investment nonetheless.

Single Stage Press

A single-stage press isn’t exactly the most efficient type of reloader. You use the lever to drive the ram through the shell holder. That goes up to a die (on most models), and then you’ve reloaded your bullet.

The process is considered to be slow because you can only do one bullet at a time, and you have to regularly switch out your die. This results in a low number of completed rounds per hour.

Turret Press

Turret presses aren’t all that more advanced than a single stage. They use a similar process with a lever, die, and shell holder, but they’re a bit bulkier. Some turret presses will have a clamp system that allows you to position them on the table.

You will still have to reload the shell each time, but the rotating multiple die spots will allow you to work faster to create more bullets per hour. Which one is right for you? To find out, visit our comprehensive buying guide to determine your next press.

Dies

The best reloading dies efficiently de-prime and resize the brass, and crimp the bullets. Purchasing them as a set will save you money.

- For Bottleneck cartridge-2-die sets packaging

- For Straight wall cartridge- 3-die sets packaging

Powder Scale

It determines how much power needs to be placed per round of ammunition.

Powder Measure

It measures the correct charge. 3 types of measures are usually used.

- Dippers

- Bench Mounted

- Electronic Dispensers

Powder Trickler

It helps to get the perfect charge weight, critical when developing loads for accuracy.

Funnel

It helps to pour the powder from the scale into the case.

Primer Pocket Cleaner

As the name implies, it cleans the primer pocket. This is important to get good seating of the new primer and to prevent any foreign material to influence the operation of the bullet.

Pocket Uniforming Equipment

It maintains equal depth and width of pocket for each brass piece.

Pocket Reamer

It removes crimps.

Case Cleaner

A case cleaner cleans the brass case before reloading, normally by tumbling the cases in an inert media along with a cleaning agent. Check out our best brass tumblers for reloading if you still don’t have one.

If you want to start with more and cleaner brass when shooting, a brass catcher is a great way to spend more time shooting and less time hunting for brass on the ground around your bench. We’ve got your back there too!

Case Trimmer

It trims off the stretched material from a case caused by firing. A case trimmer can be hand-held, bench-mounted, or power-driven. We surveyed the best case trimmers earlier this year.

Case Lube

This is important while resizing the bottleneck cases. It can be in the form of an aerosol spray, or wax or pad or lube dies.

Calipers

It measures the brass so it remains within the specs for the caliber. It’ll come in handy when measuring the cartridge length while setting the seating die.

Shell Holder

It holds the reloading cartridge.

Labels

Labels are critical to take notes of what works well and to make sure you can reproduce it! There’s nothing worse than getting a box that works really well in a gun before realizing that you can’t get the same ingredients or didn’t write down enough info to make more! You can either purchase pre-made labels or create your own.

Reloading Bench

This simple tool makes reloading more convenient with a dedicated work area. You should have one if possible.

Loading Tray

It’s an important part of a reloading bench. It helps you to do the work in small batches and in an organized way. Each batch usually contains 50 pieces. They also prevent the brass case from falling over the bench.

Bullet Puller

The best bullet puller will come in handy when you make a mistake and have to reclaim different components like bullets. Usually, three types of bullet pullers are popular.

Sometimes buying a complete reloading kit is better (and cheaper) than buying these tools individually. Check out our article about the best reloading kits if you’re interested.

Step by Step Procedure: How to Reload Ammo

Step 1: Prepare the Brass Case

Cleaning: As the brass case gets dirtier when the gun goes PEW, you’ll have to clean it first. You can either polish or tumble the brass case. Or you can simply use liquid cleaners or ultrasonic cleaners.

Resizing: Because of the explosion inside, the brass case expands immediately. And shortly after that, it goes through a shrinkage. Ultimately the case is a little larger than before. So you need to change it back to its original size.

First of all, de-prime the primer attached to the case using a reloading press.

Now run the case through a die where it’ll resize the brass. Lube up the case if necessary. It’ll also remove dents and problems on the case mount.

Next, check the length.

As the brass is squeezed down, you may have to cut off the excess length. There are both hand-based and electric options for doing that. As you’re cutting off the materials, the edges will be sharp which may cause a problem with bullet seating. So you may need to chamfer or de-burr them.

Priming: Because you popped out the primer earlier, you’d need to put in a new one. Use the priming tools to insert a new primer.

Step 2: Add Gunpowder

We recommend using smokeless powder. There are specifications regarding the bullet weight or caliber, so take those into consideration.

Check the manual for the amount of powder to start with. Use the powder measures to measure the correct amount and drop it into the case.

Step 3: Seat the Bullet

Finally, it’s time to take a bullet and place it into the prepped brass case. But the problem you may face is that the case is too narrow for the bullet. In that case, you need to flare the top of the case.

This is very common in pistol cases. To flare it, you will need a separate die or it can also be a part of your powder stage die. After flaring, just place the bullet on the top of the brass case.

Now run the bullet through the bullet seating die. You can also use a crimp to press the bullet in the case.

You’re done with that bullet! Now, repeat those steps and get back out to the range. 😉

After that, don’t forget the proper way to store your ammo. Check out our best ammo storage containers as well as our review of the best gun safes.

How To Reload Ammo Properly: Avoiding Mistakes

We’ve seen the play-by-play, but now it’s time to drop in some helpful information to ensure your safety while reloading ammo, and for you to understand a bit more about the whole process.

Over Crimping

This is something that you usually learn by trial and error. Over-crimping can ruin a bullet just as much as under-crimping.

When you load the crimp die into your reloading press, you’re pressing parts of the brass together to close off the opening in the casing.

Slow and Steady

When you’re first starting out with a new press (especially if you’ve never reloaded ammo before), it’s important to start off slow.

In the beginning, it’s far more important to load a round correctly than it is to load it quickly. Double-check every single step along the way, and don’t be afraid to toss out a round if it doesn’t work.

At worst, you’ll damage your weapon or injure yourself, and even the best options aren’t great, just ask anyone who’s ever tried to remove a squib load stuck in a barrel!

You’re learning a skill, and nobody ever became fantastic at a skill just because they had a good piece of machinery. Start off slow and steady, and you’ll win the race.

Keep Gunpowder Secure

As a general safety tip, keep your gunpowder in a container designed for it and away from direct sources of heat.

It takes roughly 801° F to ignite gunpowder, though smokeless powders can sometimes ignite in lower temperature ranges.

If you are reloading in the garage, like many of us do, keep gunpowder away from heaters and direct sunlight.

Garages get hot in the summer, so if yours isn’t ventilated, consider moving the gunpowder to a cooler spot during those months.

Multiple Reloads

You can reload a shell as many times as it will let you. If it reloads a dozen times, great. If it only reloads once before splitting, that’s a shame, but it happens.

There’s no formula to detect how long a round will last, though thinner shells, such as on 9mm rounds, may last for less time than .50 caliber rounds.

Even though the explosions are bigger in a .50 cal shell, they’re designed for it.

You don’t get .50 cal rounds sold in the same high quantity as 9mm rounds, so manufacturing quality is different.

Experiment

You’re making custom ammunition here. Experiment with the gunpowder grains, bullet weight, dies, and everything in between to get a custom round.

If you shoot at close range, you can skimp on a bit of gunpowder and save 10-20% extra of your stock for more rounds. You’ll reduce recoil and save on costs.

Cut corners where you can, because you’re not confined to a single wholesale price from a bullet manufacturer. But, stay within ranges that others have had success with until you’re more comfortable experimenting to make sure your loads are safe.

You can also use the best shooting chronograph to test your loads’ ballistics so you know which areas need improvement.

Frequently Asked Questions

What Is Ammo Reloading?

Ammunition reloading is taking the old brass casings that come off of your gun, and reloading them with new bullets, gunpowder, primers, and sealing them so that they’re just as good as brand new rounds.

Ammo reloading is a long process, especially since—even with a reloading press—you have a few steps that you have to do manually for every single casing. You’re also required to clean off your brass casings before you even attempt to load new rounds into it.

When you fire a gun, a small explosion happens when the hammer hits the primer of a bullet. That explosion has been measured, down to the literal grain of gunpowder, to perfectly fit that casing. Your bullet travels at the optimal speed without causing too much of an explosion in the gun barrel. So it’s an exact science. But the problem is, your brass casing has now had an explosion inside of it. It’s not exactly the most sturdy metal; it’s actually fairly malleable.

When you’re reloading ammo, you have to account for the fact that the casing is going to be expanded. That’s where your reloading press will come into play. If your casings completely split at any point, those are duds and cannot be reused. Those may have had a few grains too much.

Ammo reloading involves combining the above-mentioned components to rebuild a bullet from the ground up, so you can make your own custom ammunition.

Why Should You Start Reloading Ammo?

If you shoot as often as possible, you’re going through tons of bullets. The more you shoot, the more money you’re poised to save over a period of time.

You can save more than 50% off the ammo by reloading it. You can shoot a lot more range after you reloaded it. But how much money you’ll save per round depends on how expensive is the caliber. If you’re planning to reload a popular caliber such as the 9mm, we published an article that reveals the exact cost to reload 9mm. With cheaper caliber, you’ll end up saving only 10-12% of cost whereas an expensive one can save up to 50%. Plus, reloading ammo is fun!

Are you ready?

Ready to begin reloading your own ammo? Our article about 300 Blackout powder is perfect for your next read!

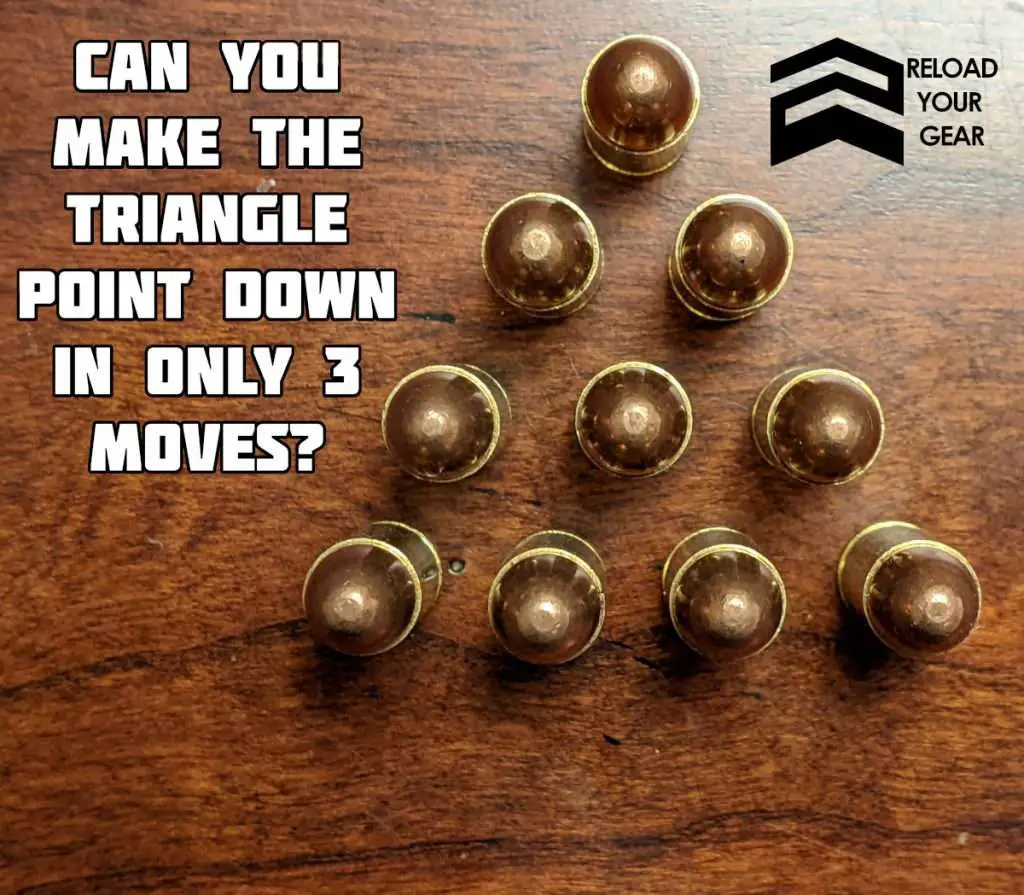

Here’s the answer to the brain teaser above. How’d you do?

Reload, Save Money, Repeat

Saving money, customizing your rounds, and being ready when SHTF—what could be better about reloading your own ammo?

Keep these tips and tricks in mind when you take up at-home reloading, and before you know it, you’ll be able to plan ahead for ammunition shortages in the future without killing your wallet in the process.

Ammo shortages are coming, but you’re going to be prepared for them so you can protect your family, and continue hunting to put meat on the table. If you want to do more research about reloading, our article on the best reloading blogs should help.